wire edm machine working principle

Parts and Working Principle PDF Hey guys in the last article we had discussed the Fuel Supply system in SIEngine and in Todays. Principle of wire cut EDM.

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Mechanical Fuel Pump SU.

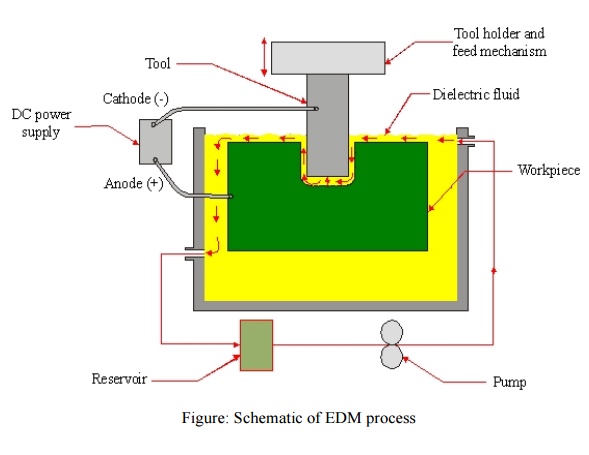

. It is suitable for thermoelectric. Electrical Discharge Machining EDM is a material removal or fabrication technology. Electrical discharge Machining Working Principle.

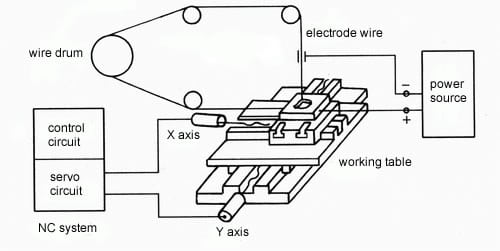

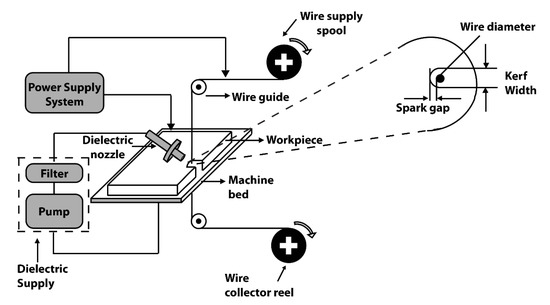

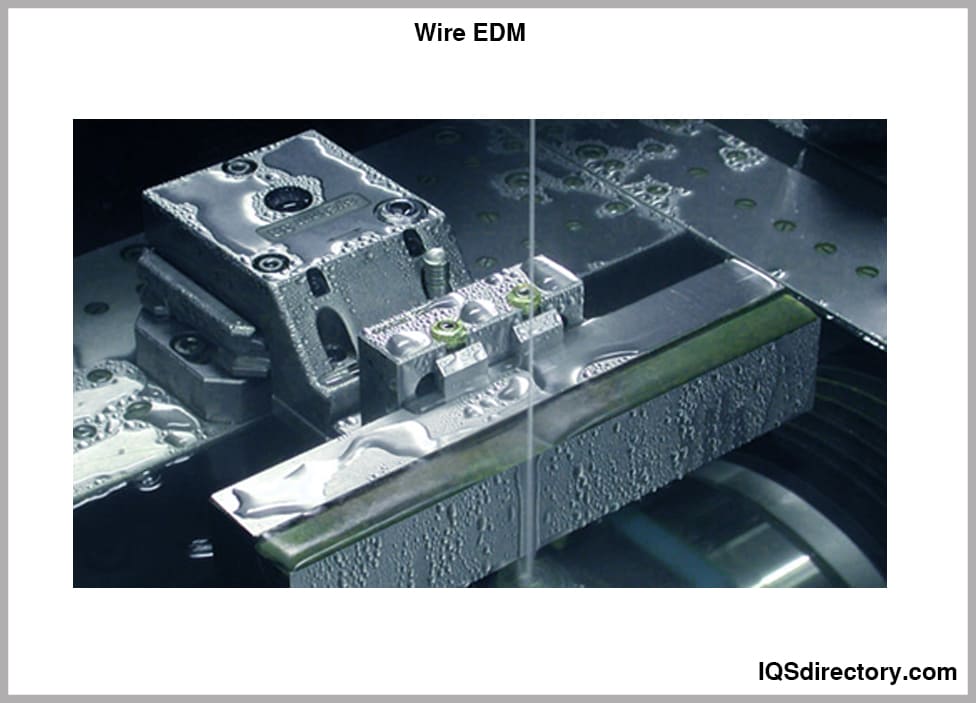

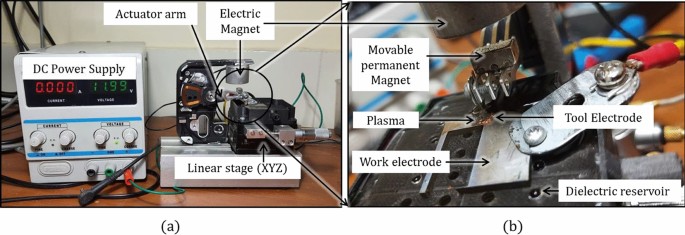

Wire electrical discharge machining WEDM uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed. Further the EDM electrode or wire is mounted on a tool post as the wire itself acts as a tool in EDM machining. 62 Hoang Tat Dat Ward 15 Tan Binh District TP.

Wire EDM Technology. The EDM wire-cut machine is a variant or type of Electro Discharge Machining where a thin electrically conductive wire generally. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always.

Ho Chi Minh Vietnam. Tool Post and EDM Electrode Tool. 0938923778 - 0908021514 Ho Chi Minh Da Nang -.

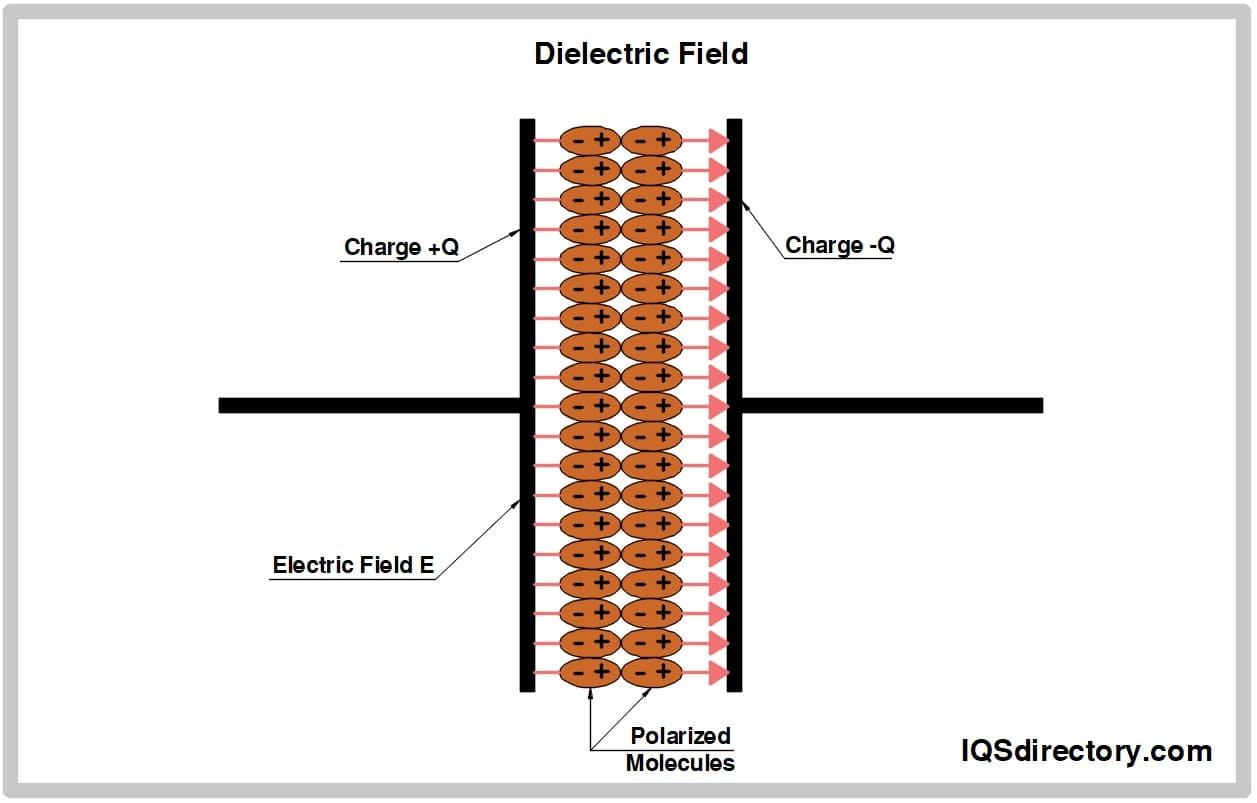

In addition to wire EDM the same principle is used today in diesinker or vertical EDM which makes a cavity in the work piece using a copper or graphite electrode in the. Other than these components. The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion.

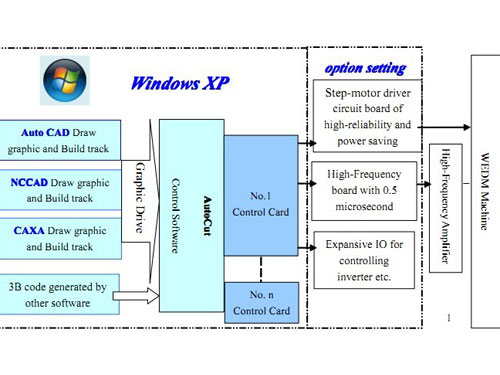

CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo system to. LAM PHU TECHNOLOGY TRADING SERVICE CO LTD. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that are very.

Construction and Working Principle Discussed. Working Principle and Performance of Wire Electrical Discharge Machining Abstract. According to the form of the tool electrode and the relative movement between the.

The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting. The term EDM stands for Electrical Discharge Machining. Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin.

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges.

What Is Wire Edm A Guide To Wire Electrical Discharge Machining

Wire Edm Wire Electro Discharge Machining Engineeringclicks

Jmmp Free Full Text Response Surface Methodology And Artificial Neural Network Based Models For Predicting Performance Of Wire Electrical Discharge Machining Of Inconel 718 Alloy Html

Electrical Discharge Machining Edm

Working Principle Of Wedm Download High Resolution Scientific Diagram

Edm Machining Components Types Applications And Advantages

What Is Wire Edm Electrical Discharge Machining Xact

A Systematic Review On Powder Mixed Electrical Discharge Machining Sciencedirect

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Edm Machining Components Types Applications And Advantages

Feasibility Analysis Of Novel Maglev Edm By Comparing With Conventional Micro Edm Scientific Reports

How Does A Wire Electrical Discharge Machining Work Neva

Working Principles Of Electrical Discharge Machining

Eds Advantages Comparing To Wedm Tech Edm Trade Co Ltd

General Purpose Cnc Edm Wire Cut Machine F Structure Beijing Dimon Cnc Technology Co Ltd